PREFAB MODULES

Modular construction

VIDALCO Prefab Modules are the new standard in heating and cooling of floors, walls, ceilings and concrete core activation.

HOW IT WORKS

Our modules are the answer to circular, industrial and modular construction.

VIDALCO Prefab Modules are the new standard in heating and cooling of floors, walls, ceilings and concrete core activation. The VIDALCO Prefab modules have several advantages for both the end user and the installation parties.

We have already applied more than 450 projects with our prefabricated products for our customers, construction contractors and installation companies. View references

Vidalco

HOW IT WORKS

Our modules are the answer to circular, industrial and modular construction.

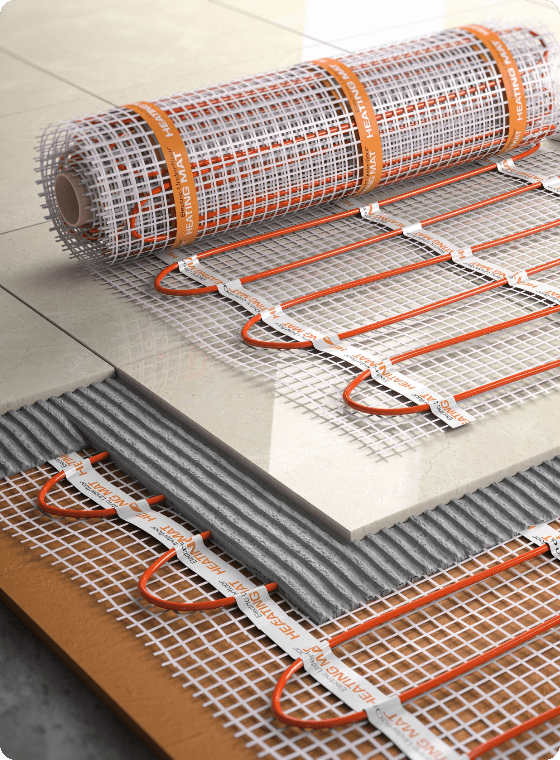

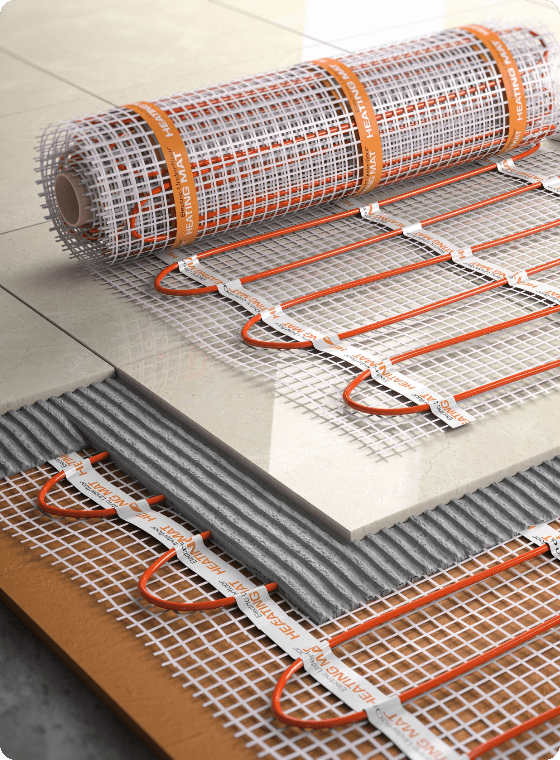

The modules are produced directly from a digital work environment, 3D in Autocad or Revit, in the required installation pattern. Production is fully automated, which means that the required production time on the construction site or workshop can be kept to a minimum.

The modules are delivered on a roll, making them very efficient to transport and process. After rolling out the modules, they remain flat, so we only have to attach minimally to the substrate for most types of finishing floors.